Plastoil WASTX Plant

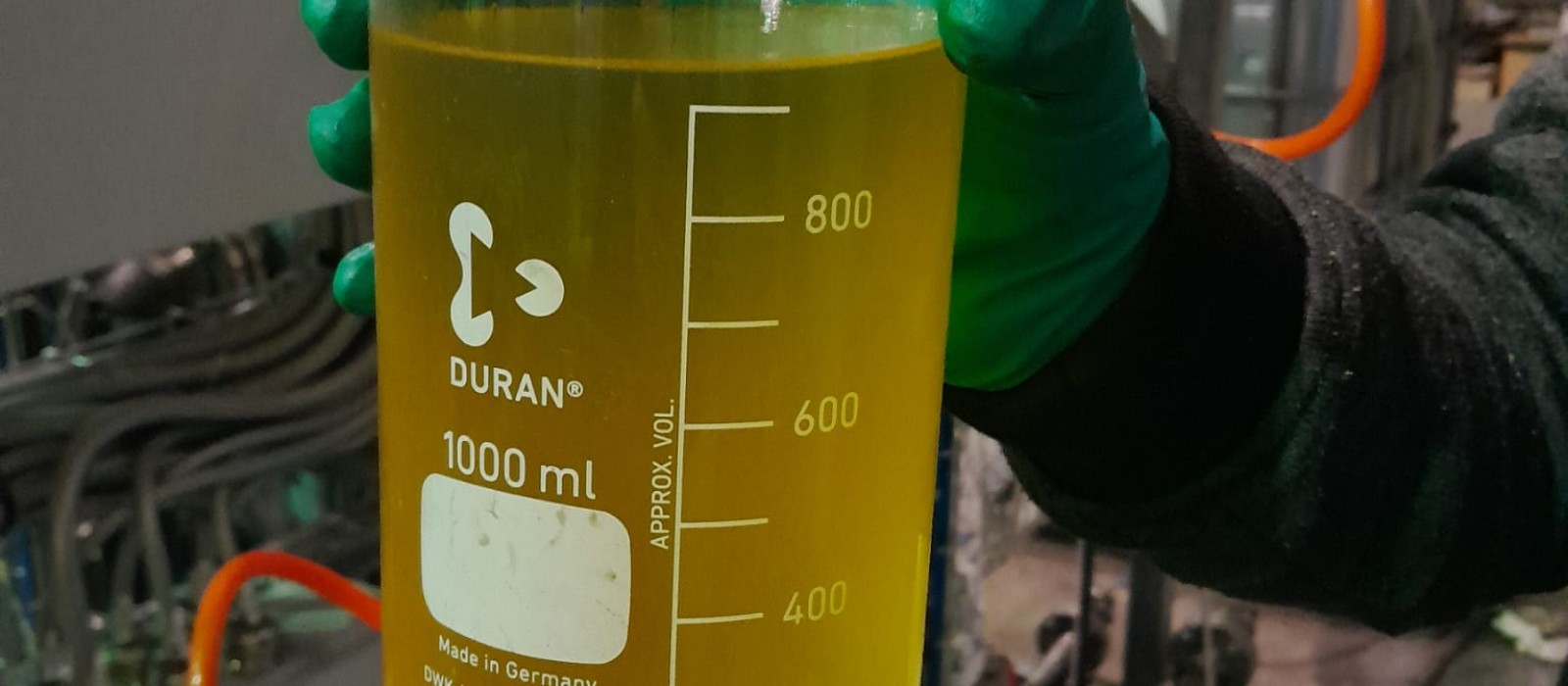

Our plastic recycling solution, WASTX Plastic, is a unique mobile technology for effective conversion of plastic waste into pure, high-quality resource oil, that can be directly used in industry and community.

THE SOLUTION TO THE PLASTIC WASTE CRISIS?

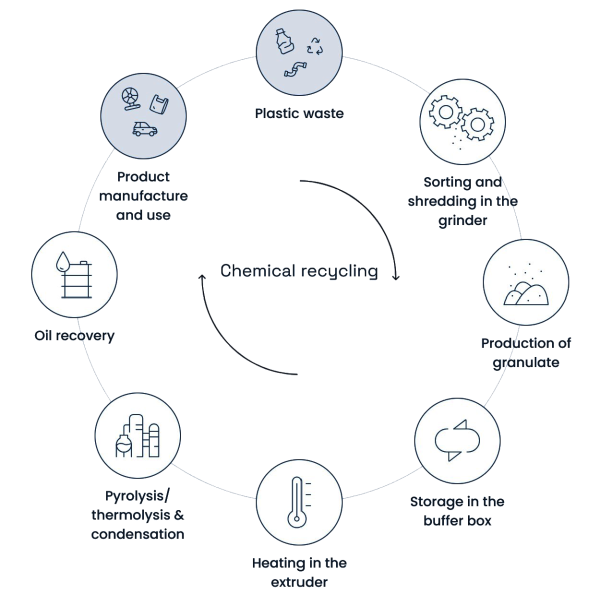

Plastic is primarily derived from crude oil. In order to reverse the process, we began to focus on chemical recycling, particularly pyrolysis. After more than a decade of research and development, we achieved exactly that with our WASTX Plastic technology. In a continuous and automated way, post-consumer plastic waste is recycled into bio-oil and energy.

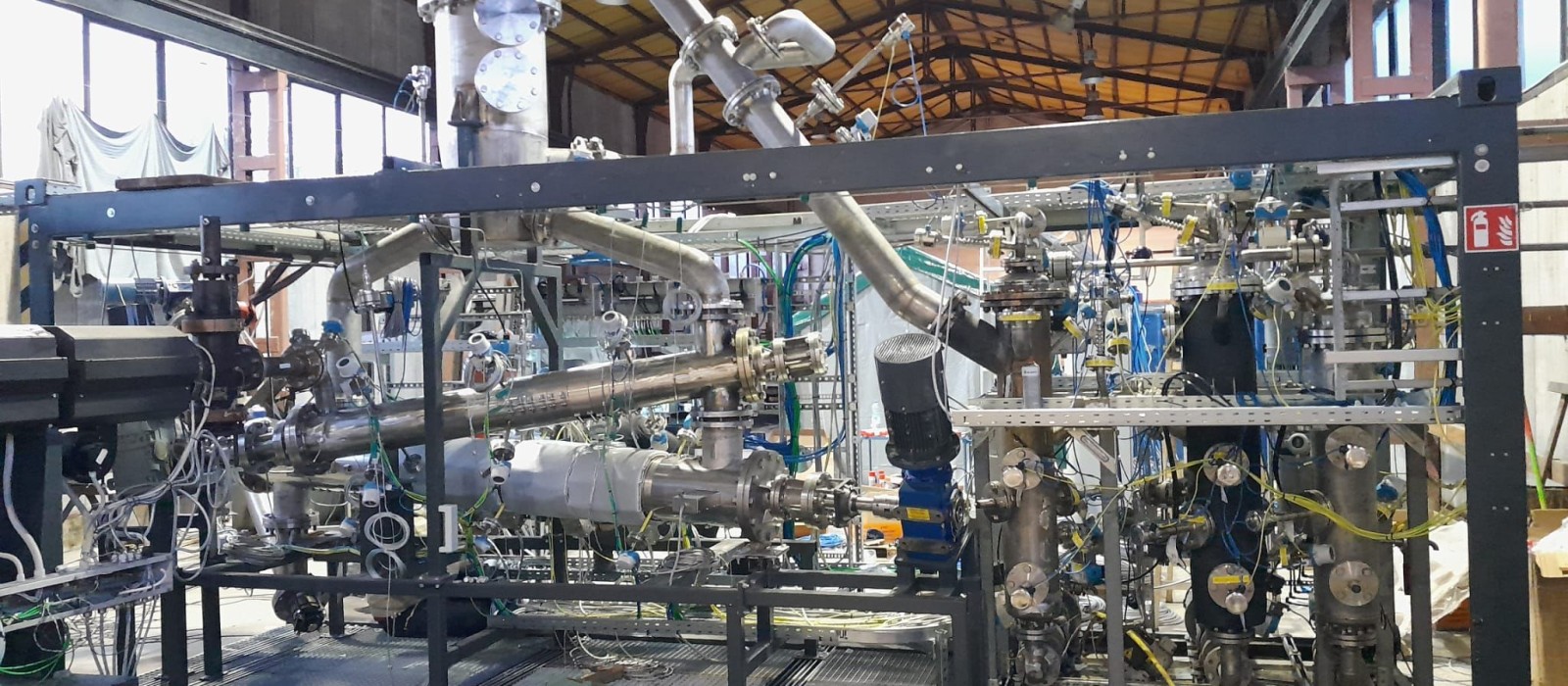

STATE-OF-THE-ART TECHNOLOGY

The WASTX Plastic technology offers advanced modular construction with pre-treatment options and scalability from 2.5 to 200 tons per day. Thus, ensuring flexibility and efficiency.

The highly-automated technology is containerized and compact, effortlessly fitting into ISO 20ft & 40ft HC containers for seamless global delivery.

Plastic-to-oil systems

| We offer decentralised small, medium and large systems. | Input (plastic numbers) | Throughput | per hour |

|---|---|---|---|

| WastX P1 | 2, 4, 5, 6 | 1 tonne/day | 42 kg |

| WastX 2.5 | 2, 4, 5, 6 | 2.5 tonnes/day | 105 kg |

| WastX P5 | 2, 4, 5, 6 | 5 tonnes/day | 210 kg |

| WastX P25 | 2, 4, 5, 6 | 25 tonnes/day | 1040 kg |

Plastic pollution is reaching its highest levels ever and it impacts our lives in ways that we do not realise.

Our mission is to provide solutions for the plastic crisis in the locations it occurs - and this is why our WASTX Plant can be installed anywhere where plastic waste is accumulated.

Get answers

- 1 kg of plastic produces 1 litre of oil.

- 4% of the output consists of carbon black and ash, which have commercial value and can be sold in the open market.

- 12% is syngas, which is utilized to power the unit itself.

For information on PP, PE, HDPE, and LDPE, please refer to the plastic numbers sheet.

We do not process PVC or PET. Although we can accept PET, it may affect the yield. A feedstock specification can be provided on request.

The units are self-contained, with minimal to no smell or emissions. The emissions are safer than a standard home gas chimney stack or comparable to Euro 5 standards, depending on how the unit is implemented on-site.

- Our technology is delivered as a fully turnkey solution. It includes delivery, permitting, commissioning, and comprehensive staff training.

- The customer is responsible for providing infrastructure such as the building, power supply, water, and vehicle access.

We assist customers in achieving ISCC Plus certification for the oil, ensuring it is fully circular if desired. This enables refineries to process the oil and work with our downstream partners to produce resin for new plastic products.

A typical installation for a 5-tonne-per-day unit can be completed in approximately six months, depending on shipping and site-specific factors.

All our equipment is manufactured in Germany, adhering to the highest EU quality and safety standards.

Plastoil has a story,

where plastic waste becomes a valuable raw material.

Plastic pollution is reaching its highest levels ever and it impacts our lives in ways that we do not realise. Our oceans and wildlife are the ones feeling the effects of this plastic waste first hand.

Fact 1.

Every year, we produce more than 300 million tonnes of plastic waste. This figure is almost equivalent to the weight of the whole human population.

Fact 2.

Oceans are one of the most severely impacted habitats, which receive hundreds of tons of unwanted plastic waste every single day. The result? According to the UN, annually more than 100 million animals die because of the plastic waste, scattered across the oceans.

Fact 3.

More than 500 marine locations with a total size equal to the one of the United Kingdom (or 242,495 km² ) are pronounced 'dead' - which means that no animal life can be sustained anymore.

Get in touch

Plastoil represents the Enespa Group, who specialise in manufacturing the latest plastic recycling technology. Manufactured in Germany to meet all EU Emissions and safety standards. We are representatives for the Australia, New Zealand and Asia Pacific region.

Get in touch with Plastoil about your project. If you still have questions or require more information, we are here to help and provide solutions that help solve the plastic waste problem the world is facing.